Plastic Recycling At Home Or In The Classroom

To illustrate or play with the idea of recycling you can plastic recycling at home or in the classroom. All you need is some acetone, a several pieces of Styrofoam and a small bowl.

(Polystyrene is a petroleum-based plastic made from the styrene monomer. Most people know it under the name Styrofoam, which is actually the trade name of a polystyrene foam product used for housing insulation. – Yahoo Answers)

Ideally, you should wear some chemical resistant neoprene gloves while using acetone. Pour the acetone into the bowl and then begin to add the Styrofoam pieces.

Watch the Styrofoam melt.

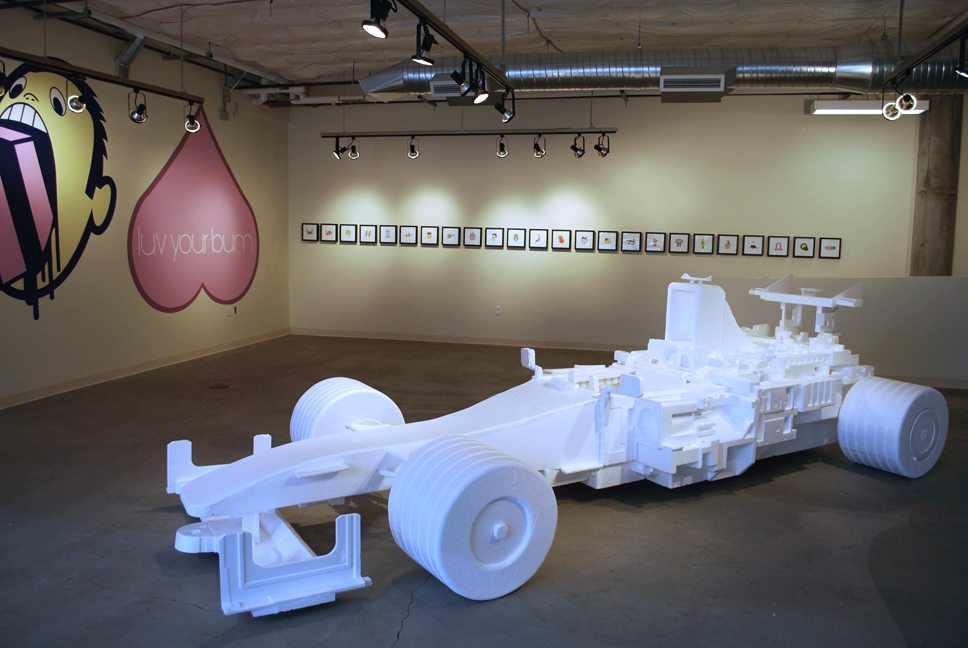

After the material has melted you can mold anything you’d like.

Let your new creation dry for a few days, add some paint if you’d like and you now have and object lesson in how plastic scrap can be upcycled into a new product. Using old expanded styrene (styrofoam) is a brilliant idea for making models and the like. However handling acetone should be done in a well ventilated area, away from sources of ignition as is flamable.

Another example of how to do plastic recycling at home or perform an experiment in your science class is to working with some plastic that is safe to melt. The plastic material symbol #2 (HDPE) plastic scrap is a good example.

Place the plastic in the oven at 350 degrees fahrenheit and remove it out when it has melted. Depending on how large the scrap is, you can let it harden for an hour or two until it has become strong and solid. sit for an hour or 2 depending on the amount of plastic and then it will be solid and very strong you can make whatever you want.

You can use some drops of food color or carbon black for colorants and it is possible to make the material harder by adding some glass fibers from house insulation, or wood stove door seal material. If you can manage to tease the fibers into long strands, and orient the strands along the lines of the part’s desired strength, you would probably end up with a stiffer finished product.

Leave a Reply